3D Printing 101

- dynamic3dservice

- Jan 21, 2022

- 6 min read

Updated: Jan 15, 2024

If your new to 3D printing this is a great article to learn the basics of the technology.

3D printing is a technology that has been around for quite some time, since 1986 in fact. An inventor by the name of Chuck Hull is accredited as the first to file a patent related to the 3D printing technology.

So why am I just hearing about it?

As with any technology there was a period of development and integration that had to happen to make this technology truly useful and cost effective. After several years of research into materials, 3D modeling software, and cost effective design we began to see machines that were checking all the boxes. The last few years or so represent what I might call the prime era for this technology. We have reached a point where the machines are cheap enough for the general market to bear. Materials are abundant and of numerous compositions to cater to many different use cases. Yet, arguably the most important factor is demand. This technology makes fast prototyping of unique 3D objects much cheaper than other manufacturing techniques. For this reason public interest in 3D printing has grown exponentially in recent years and the trend shows no sign of slowing down. Continued research and development has pushed the limits of this technology and we can see the beginning of its use in the medical industry printing organs, and even in construction where we are printing entire houses.

What is 3D printing?

3D printing, also known as additive manufacturing, is generally the process of building 3D objects by adhering 2D layers together one on top of the other. By stacking these layers we eventually get a 3D dimensional object. However, there are a few different ways in which we can achieve this.

What types of 3D printing are there?

The ways in which we have found to essentially stack layers is impressive. These method include:

Fused Deposition Modeling (FDM)

Stereolithography (SLA)

Digital Light Process (DLP)

Selective Laser Sintering (SLS)

Multi Jet Fusion (MJF)

Direct Metal Laser Sintering (DMLS)

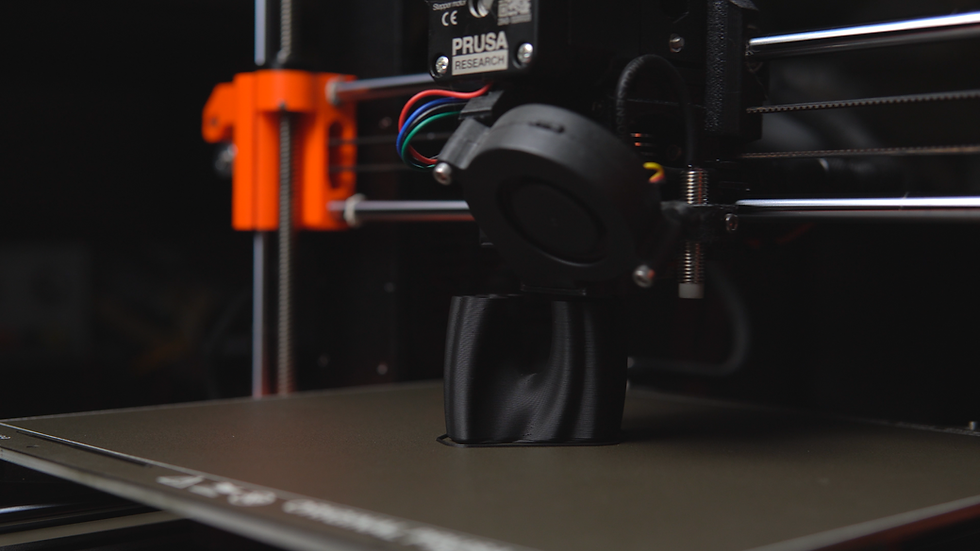

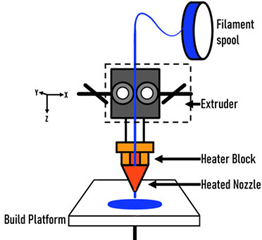

FDM is the process most people are familiar with as it is the cheapest and most common type of printer available for hobbyists and home use. This type of 3D printing works much like a hot glue gun. Instead of a glue stick it uses filament which is a spool of thermoplastic. The filament is fed into the hot end of the printer which melts the thermoplastic filament and deposits it on the print bed through an extruder to ensure consistent flow and shape. The extruder moves around the print bed to lay down 2D layers by way of a gantry system. This gantry system usually consists of stepper motors that can move the extruder in X, Y and Z directions or rather UP-DOWN, SIDE-TO-SIDE, and FORWARD-BACKWARD. This allows the extruder to deposit material in a 3D space. Once a 2D layer is complete the extruder moves up and begins another layer on top of the previous fusing the two as it goes.

The drawback of this type of printing is that the surface will contain layer lines. There are techniques to reduce the appearance of these lines but they cannot be fully eliminated. Sanding and painting can remove layer lines in post if necessary but it can be challenging if the shape is complex.

However, the low cost of this method makes it a great option for building strong and functional parts. Another benefit is the material options. Filament is available in a variety of thermoplastics and composites. Common thermoplastics include PLA, ABS, PETG, NYLON, POLYCARBONATE, and TPE-TPU-TPC (Flexible). Special composites include wood-filled, metal filled (aluminum, bronze, copper) carbon fiber composite, glass fiber composite,glow-in-the-dark, conductive, color changing, dichromatic, clay, wax/castable, water soluble (support material). As you can see there are a lot of options.

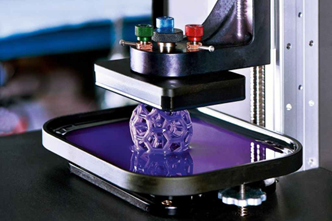

SLA and DLP are very similar processes. Both use photopolymers which are a liquid that is cured or hardened using UV light. The main difference between the two is their source of UV light. SLA uses a laser that traces out each layer while DLP uses a projector that illuminates the entire layer at once. In both cases once a layer has cured it is lifted further out of the vat containing the photopolymer resin. This leaves room for another layer to be cured underneath the previous. In the end the entire model is lifted out of the vat as a 3D object. This process is capable of creating very dimensionally accurate parts with a surface finish that is smooth.

The one drawback ,however, is that after the model is removed from the printer it is slimy with residual resin and a bit soft which means these parts require post processing. Each print must be washed with alcohol to remove any excess resin clinging to the surface of the part. Following that each part must be cured inside a UV chamber to fully harden into a usable object. This type of printing also has abundant options for materials. All materials must be photopolymers but there are a variety of formulations that result in different structural properties. There are some designed for strength while others can produce completely translucent objects like glass.

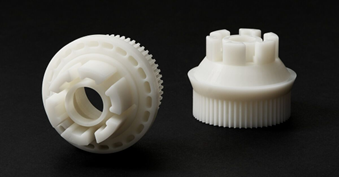

SLS is a process that doesn't use resin or filament but instead a very fine thermoplastic powder. First, a very thin layer of this powder is applied to the print bed. Then, a laser traces the outline of the 2D layer fusing particles of thermoplastic powder together as it passes. Then another coat of powder is applied and laser fused. This is repeated until the object is complete. The combination of the fine powder and a laser results in very accurate parts and no layer layer lines. Post processing is required as the part will be buried underneath a pile of residual powder. Coincidentally this powder also acts as support material for the part as it fills in any cavities in the model as the part is built. Afterward, all the powder must be removed from the part by air blasted, vacuuming, brushing, or other means. The powder can be reused for future prints.

SLS printing is an attractive option for large scale 3D manufacturing as it can produce dimensionally accurate parts with a smooth finish in high volume. Due to the powder there is no need for support material. This also means parts can be tightly packed and even stacked on top of each other. This makes for very efficient use of space and higher output overall. The drawback being labor required for post processing that can't be automated and high cost of SLS printers. These printers can range from $20,000 to upwards of $200,000.

MJF has many of the same properties and functionality as SLS but a different method in achieving it. The primary difference is the binding process. While SLS uses a laser MJF using an ink fusing agent. In MJF printing ink is dispensed over the powder. This ink absorbs infrared light. After the ink is in place the infrared light source illuminates the layer and the ink absorbs the light heating the powder and fusing it. As with SLS the powder must still be removed in post processing and prices for these machines are similar to SLS.

DMLS again is very similar to SLS. The major difference here is that the powder is not a thermoplastic but rather a metal. All else in the process is generally the same. Metal powder is applied to the bed and then a laser traces the layer pattern and sinters the metal powder together. In the end a dimensionally accurate part is created out of metal. This technology is particularly useful for creating complex metal parts that could not be manufactured easily any other way. Similar to SLS, these machines are very expensive.

What types of things can I 3D print?

3D printing is an extremely versatile tool. Almost any object can be 3D printed but the real question to ask is what should you 3D print? In 3D printing custom is the name of the game. When developing new parts, tools, and fixturing, it's a great way to bring that design into the real world for test fitting and verification. It's also useful for creating objects that can’t be easily machined or manufactured any other way. Objects that have complex surface features, curves, or voids. This can also mean organic shapes like an apple, animals, or figurines. 3D printing is well suited for creating custom solutions. An example might be a part that broke that is no longer produced and can’t be cheaply machined. In this case 3D printing a copy might be the perfect solution. Another unique attribute is the ability to use a 3D scanner to scan an object and 3D print a replica. There are so many possibilities when it comes to 3D printing but it's not without its drawbacks. 3D printers have a limited print volume so large objects are not great for 3D printing. Another thing to consider is that most 3D printed parts are made of plastic so these parts should not be put under heavy stress or load or be used for anything of a critical nature.

As has been discussed, 3D printing is an extremely versatile manufacturing technique for producing unique parts that in some cases can’t be created using other manufacturing methods. I hope this article provided you with a high level understanding of what 3D printing is and what's possible with this technology. If you're interested in learning more about 3D printing check out our other articles on the topic. As always if you need to do some 3D printing yourself let us know and we’ll help make it happen.

.png)

Comments